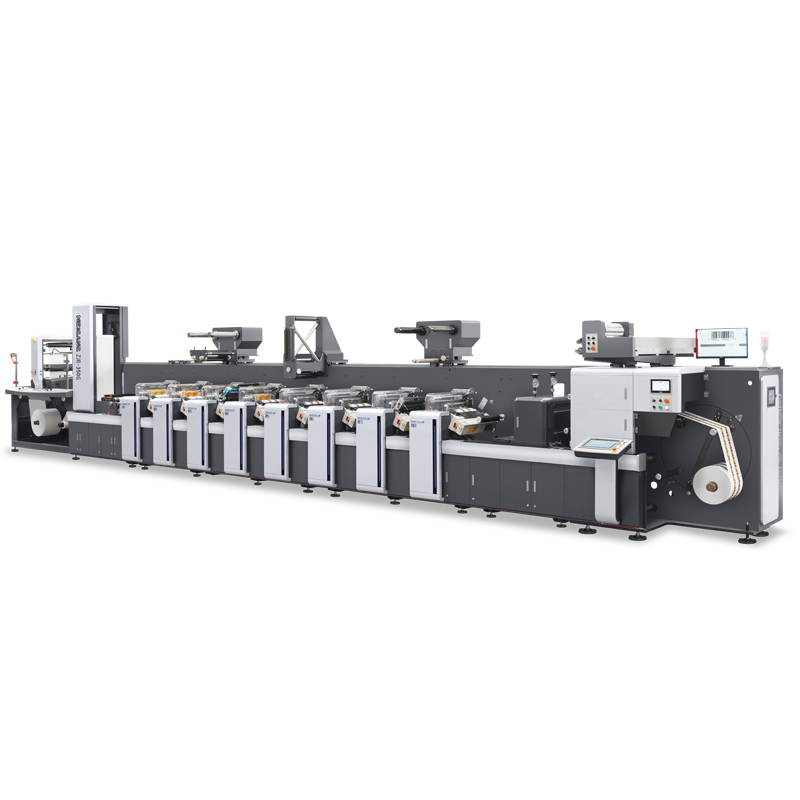

Flexo Printing Machine-ZJR-350G/450G/650G

1. The whole machine adopts the latest servo control system from Germany and each printing unit is driven by independent servo motor. There are 23 servo motors in total for 8-color machine which ensure the accurate registration during high speed running.

2. The printing roller adopts sleeve system which is light, easy, convenient and fast to change. This type of design largely improves the printing quality and reduces the maintenance

online service

Main Features

1. The whole machine adopts the latest servo control system from Germany and each printing unit is driven by independent servo motor. There are 23 servo motors in total for 8-color machine which ensure the accurate registration during high speed running.

2. The printing roller adopts sleeve system which is light, easy, convenient and fast to change. This type of design largely improves the printing quality and reduces the maintenance

3. Fast and easy pressure adjustment of printing or ink transferring: Printing roller run by bearer, it’s not necessary to adjust the pressure when changing the roller, or at most fine adjustment for special job.

4. Anvil roller equipped with water chiller, which is good for film material.

5. Suitable for printing variety film material, such as PET, OPP, CPP, PP and so on.

Main Technical Parameters

-

Sleeve

The printing roller adopts sleeve system which is light, easy, convenient and fast to change. Since there is no gear on the cylinder ,it largely improves the printing quality and reduces the maintenance.

-

UV Dryer and Anvil Roller with Water Chiller

UV curing is equipped with water chiller, which lowers the temperature of flexo plate while printing. It reduces the friction between plate and material, improves the quality of printing and enables the machine to print variable film material, such as PP,PET,BOPP,etc.

-

Movable Turn Bar

When the material needs to be printed on both sides, it can be completed at one time by turn bar.

-

Matrix Unit

It is snowball matrix device with a good performance, the speed is synchronized with printing.

-

Movable Touch Screen

Touch LCD screen, faster CPU, 15inch operating display. The rich human-computer dialogue system, multi-guide inspecting display interface, instant alarm signal, makes operation much easier and more efficient.

-

Die Cutting Roller Lifter

It is an electric lifting device for changing magnetic rollers , convenient and fast.

Expert of Label Printing Machine

Expert of Label Printing Machine

-

*Hot Air Dryer(Option)

Using wind knife drying method, good effective for water-base ink and solvent ink drying.

-

*Movable Cold Stamping (Option)

It can be movable on the railway of the machine, high speed and efficient.

-

*Slitting Unit (Option)

In order to improve production speed, pneumatic knife can do slitting function on line . The slitting pressure is adjustable.

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

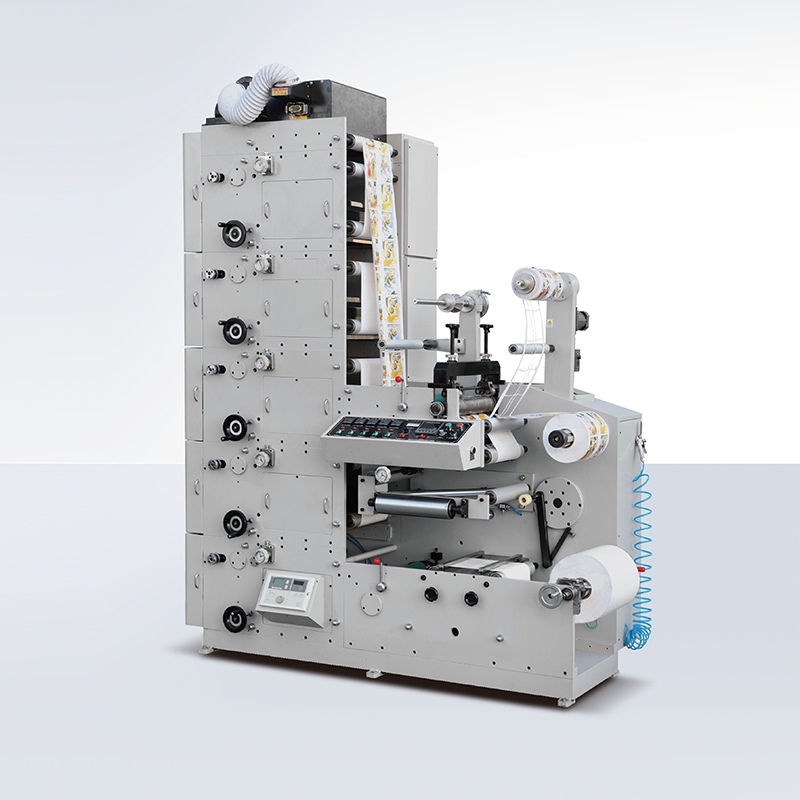

Stack Flexo Press ZBS-320/450

1. Adopts the ceramic anilox cylinder to transfer the ink.

2. Unwinding and rewinding are controlled by magnetic powder brake/clutch.

3. Each printing unit adopts 360°plate adjustment.

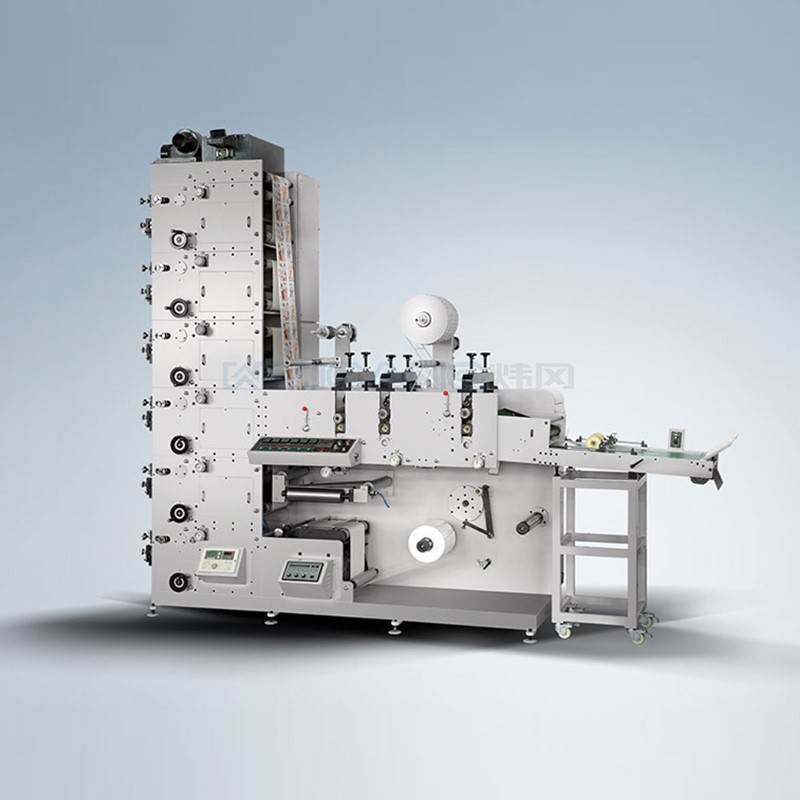

Label(logo) Flexo Printing Machine With Three Die-cutting Stations-ZBS-320G/450G

1.Adopt the ceramic anilox cylinder to transfer the ink.

2.Each printing unit adopts 360° plate-adjustment.

3.Three die-cutting stations, the first and second die-cutting station can do double sides working, the third die-cutting station can be used as sheeter.

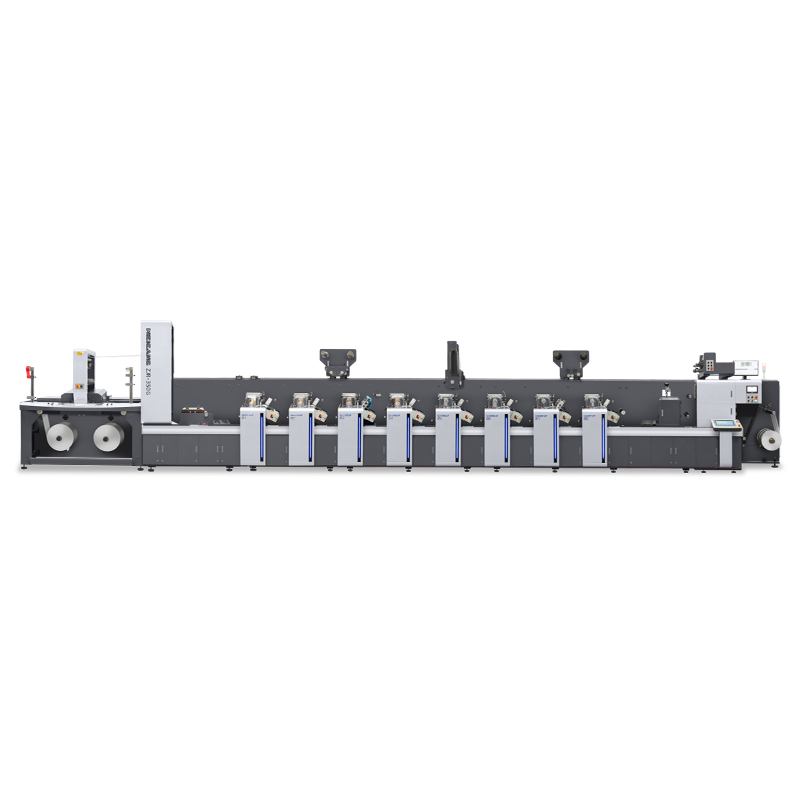

Label(logo) Flexo Printing Machine ZBS-320/450

1. Adopt the ceramic anilox cylinder to transfer the ink.

2. Unwinding and rewinding are controlled by magnetic powder brake/clutch.

3.Each printing unit adopts 360°plate adjustment.

4.Each printing unit equips with hot air dryer.

5.This machine with one die-cutting station, which makes printing and die-cutting can be finished in one process.

Flexo Printing Machine-ZJR-350G/450G/650G

1. The whole machine adopts the latest servo control system from Germany and each printing unit is driven by independent servo motor. There are 23 servo motors in total for 8-color machine which ensure the accurate registration during high speed running.

2. The printing roller adopts sleeve system which is light, easy, convenient and fast to change. This type of design largely improves the printing quality and reduces the maintenance